Insulating Suspended Timber Floors

Question: Could you please advise me on materials for under-floor insulation? We live in an Edwardian house with standard floorboards which are fixed to joist? What can we use? I was told about fibreboards.

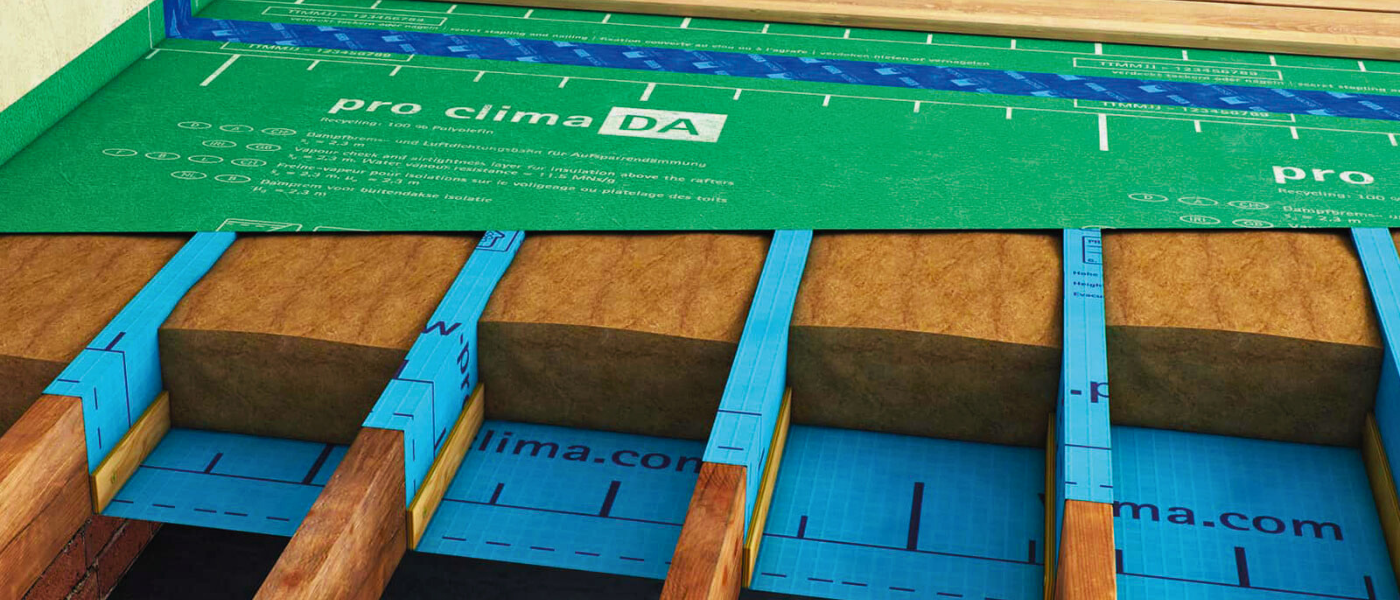

Answer: Ideally a fibrous insulation such as mineral wool or sheep’s wool performs best between timber because it will take up thermal movement and cut down air movement around the insulation. ‘Thermal bypass’ affects performance, so cutting out draughts is preferable. The insulation would need to be secured ideally with a taped membrane (a vapour open membrane such as Solitex FRONTA WA taped at joints such as Tescon Vana would be ideal) stapled to the underside of the joists to cut down air movement around insulation (thermal bypass) which tends to ‘wick’ heat from the building. This membrane must be vapour open to stop interstitial condensation.

Of course this all depends on the access under the floor! If there is no access from below your alternatives are to take up the floor boards completely, or take up a couple of boards every say metre and pull insulation through, refix boards.

Best Practice for Insulating a Suspended Timber Floor

Answer: We will try to make general comments, though obviously individual buildings will vary hugely. When insulating a suspended timber ground floor, it is important to distinguish between airtightness and wind tightness. This is because you need to avoid condensation forming within the floor structure and the potential problem of rot forming. For your particular project you will need to end up with a higher degree of airtightness than would normally be expected, to achieve the best out of the proposed heat recovery ventilation system (MVHR).

It will be important to stop warm moist air from entering the floor structure by installing a ‘vapour closed’ membrane of some kind. This could be tongue and groove chipboard, for example, with carefully glued joints. I would also suggest that, to cut down thermally diminishing air movement around insulation, you install fibrous insulation between the timber joist such as mineral wool or sheep’s wool to take up any seasonal movement in the timber floor joists as the quickest insulation method. If you used rigid insulation such as polyurethane it would need to be ‘foamed’ at the edges for the same reason.

If the underneath of the floor is accessible, a ‘vapour open’ membrane (such as Solitex FRONTA WA taped at joints with Tescon Vana) could be installed to again cut down air/wind movement and hold the insulation in place. To cut down air movement through the unplastered sections of wall between the floor joists ends, we would suggest a weak sand/cement parging coat. To get good airtightness at the edges of the chipboard floor and the plastered wall, you could use a specially designed ‘vapour open’ tape (eg Contega Exo) with proprietary mastic (eg Orcon F) hidden by the skirting board. Alternatively just use the Tescon Vana tape with Orcon F adhesive. The Tescon Vana tape is not breathable but is robust and long lasting.

The issue of condensation forming around the joist ends within the wall is often a concern in refurbishment work. In our experience, if the escape of warm moist internal air into the external wall is minimised, and the outside ground level is well below the joist ends, there will not be a problem.

Insulating a Suspended Timber Floor

Answer: There are two aims when insulating floors:

- Insulation

- Windtightness to cut down draughts and also to minimise ‘thermal bypass’. This is to minimise the passage of air around the insulation cutting out the ‘wicking’ of heat from the building.

If you can access the floor below we would suggest the following:

Our preferred method would be using fibrous insulation such as sheep’s wool, hemp, fibreglass, rockwool etc and not rigid board because it works better between timbers as it takes up any imperfections and movement of the timbers.

You can then install a ‘vapour open’ membrane (such as Pro Clima Solitex FRONTA WA) below your floor joists if you have crawling space. It has to be vapour open to allow the exit of any moist warm air to stop interstitial condensation. Taping the joints with Tescon Vana would make an even better job.

To cut down further on draughts applying a weak sand and cement parging coat to the masonry between joist ends and the gap left between wall plaster and floor is very effective.